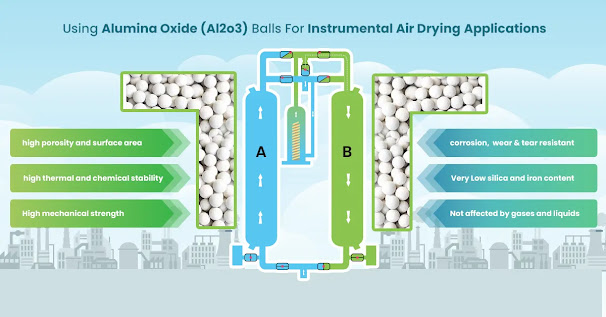

Traditional methods of air drying have a lot of limitations, and lead to inconsistent moisture levels, and air quality when using low-quality desiccant varieties and types. Using alumina oxide (al2o3) balls for instrumental air drying applications can be an effective solution, across various industries, enhanced moisture absorption, improved thermal stability, and overall cost-effectiveness.

They have high porosity levels in their material and a vast surface area that can efficiently adsorb moisture levels, and help with separation, and purification of surrounding air, improving its quality, removing humidity from the air, and resulting in better air drying capabilities.

Properties of Alumina Oxide (Al2O3) balls for instrumental air drying applications

Al2O3 balls are best suited for air drying applications due to their many properties and factors. Some of them are as follows.

- They have high porosity and surface area which helps adsorb a lot of moisture, contaminants, and impurities from the surrounding air, leading to high air drying quality when used for packaging, or industrial applications. Alumina Oxide ball’s porosity makes them effective as a dryer and reduces the chance of saturation, meaning that the dryer can absorb moisture for a long time without losing its effectiveness.

- Alumina oxide balls have a high thermal and chemical stability, which means they do not damage, disintegrate, or lose their efficiency and maintain stability even at high or varying temperatures, making them suitable for instrumental air drying processes that involve elevated temperatures. Al2O3 balls are also chemically inert, which means, they can work with a wide range of chemicals, acids &alkalis, and they do not react with the substances around them during the industrial process or application.

- These alumina balls have high mechanical strength, which makes them durable and long-lasting, and they can be used for long periods of time in instrumental air drying applications without significant wear and tear to their structure or functionality, and in turn reducing the need for frequent replacement or maintenance. They are also very hard structured, which makes them more resistant to wear and tear that they may encounter during various heavy-duty industrial applications. This is important for applications where the dry desiccant may contact with abrasive particles in the drying process.

Various applications of Alumina Oxide balls in instrumental air drying

In the pharmaceutical industry, it is used for drying granules and powders, as consistent moisture control ensures medication stability, extended shelf life, and proper dosage accuracy. It is also used for protecting sensitive ingredients, as it helps minimize moisture-induced degradation and preserves the potency of active ingredients. It is suitable for all types of dryers- heatless air dryers and heat of compression air dryers

In the textile industry, the alumina oxide balls are used in air drying applications for machinery and instruments to remove moisture from parts and maintain the quality of finished products. Excess moisture or humidity levels can damage and deteriorate textile quality and thus optimum moisture levels need to be maintained during packaging, storage, and transit.

In the electronics industry, Alumina oxide balls are widely used for example in the semiconductor manufacturing processes and other storage and transportation applications. Due to their electrical insulating characteristics and their resistance to contamination, alumina balls are well-suited for moisture prevention in sensitive electronic devices.

We provide the highest quality activated Alumina Oxide (Al2O3) Balls for all your instrumental air drying applications and processes to ensure the best results, durability, and moisture-free environment, whatever may be your industrial setting and application. You can use them to maintain optimum dry air levels during packaging, storage, and transportation too. Make sure to check out the website and reach out to us in case you have any queries or want to enquire about our innovative activated alumina ball and other products. For more Deatils - https://www.activatedaluminaballs.com/blogs/using-alumina-oxide-al2o3-balls-for-instrumental-air-drying-applications

.jpg)